So, about a week ago Alan wrote a great post about

Goals, Discipline and Dr. Who. I was a little stunned when he laid out his goals for all the world (or at least a few hundred readers) to see. Not stunned by the goals - we talked about those together - but stunned that that was being so open about sharing them. But then I thought about all the makers I follow online - craftspeople and authors who are working on making a living from their creativity. I would LOVE to know what goals they're working toward, what steps they're taking to build their careers, the thought process behind the decisions they're making. So I'm going to share too.

Five year plan (deadline January 1, 2015 - yikes!)- double my income (ahem, not the task it would have been a couple of years ago when I had a big corporate job)

- quit my day job

- establish Shiny Happy World as a cohesive brand (in other words - stay focused)

- design a line of fabric

- be a more active member of the online craft community (I tend to be a lurker)

- be a healthy weight

- attend ALA and IRA as a vendor

One year plan (deadline January 1, 2011)- sell another book

- release doll pattern (Lucy, Abigail and Becky)

- release pattern for Shiny Happy Softies (bunny, bear and chick)

- design Bookish Girls

- design Pirates and Ninjas dolls

- design and line of hats

- buy and read Lizzy House's e-book about designing fabric

- teach classes for adults and kids

- interview a maker every month on the blog

- feature handmade items I love at least once a week

- build relationships with ten wholesale accounts

- lose 30 pounds and keep it off

- exercise five days a week

So how am I doing so far?

In January I reached exactly 2% of my sales goal. Ouch. So the rest of that goal got rolled in to the next 11 months. And I'm already at 21% of my February goal - so that's an improvement.

I have a logo for Shiny Happy World and a new focus for my work - and for the first time ever I think everything in

my shop looks like it goes together. I decided to stop fighting my tendency to make cute things and instead embrace that part of my spirit. I spent 20 years working with children's books for a reason - I like cute things, colorful things, cheerful things, silly things - shiny, happy things. I smile

every time I finish a bunny - and I give him a little hug before I drop him in a basket. I

love giving my girls just the right name. My paper-cut logo makes me happy and helps keep me focused.

I have

one wholesale account now, with three more possibilities in the works.

I've lost 9 pounds so far and I've exercised more consistently than I ever have in my life. And I still eat dessert every night - very important. :-)

I've finished designing and testing the patterns for

dolls and

Shiny Happy Softies - I just need to finish photography and get the patterns laid out.

I'm teaching a

class for adults at Penland this spring (there's still room if anyone wants to sign up), and I'll be teaching summer camps for kids at Penland and Spruce Pine Montessori School.

I just sent out a batch of i

The water in our chicken coop keeps freezing! What's a backyard poultry farmer to do? Build a homebrew chicken water warmer. Here's how we did it:

To start, you'll need a large tin coffee can, or something comparable. It just needs to be metal.

Next, buy an "Electric Water Pipe Freeze Protection Cable," also known as a "Pipe Heating Cable." These are supposed to be used for keeping exposed pipes from freezing. Our local Ace Hardware had a nice selection of lengths. For this project, you'll want the one that's just three feet long. Out of the box, they look like this:

The black part is the heating cable.

The larger orange case is the thermostat, and the black circle is the sensor that must be touching whatever you need to keep warm. This Easy Heat model kicks on when the temperature falls to 38 degrees Fahrenheit, and warms the water until it reaches 45 degrees F. The documentation says it works down to -38 degrees. If that claim is ever tested, our chickens are going to have bigger problems than a frozen water dish.

Meet our chickens! We are now the proud owners of five hens and one rooster. Here they are in the crappy old coop we inherited. They're waiting and watching while we build their new, deluxe accommodations:

Meet our chickens! We are now the proud owners of five hens and one rooster. Here they are in the crappy old coop we inherited. They're waiting and watching while we build their new, deluxe accommodations:

We based our design on plans we found online (opens as a PDF) for an a-frame chicken coop, but we improvised a bit in the construction. We initially tried to use metal sawhouse brackets to join the top, but they didn't give us the wide base we wanted.

We based our design on plans we found online (opens as a PDF) for an a-frame chicken coop, but we improvised a bit in the construction. We initially tried to use metal sawhouse brackets to join the top, but they didn't give us the wide base we wanted.

After the frame was built, we added a floor with a door cut in it. The gangplank to get inside would be added later.

After the frame was built, we added a floor with a door cut in it. The gangplank to get inside would be added later.

Here's Jo, pretending to be a chicken as she comes inside.

Here's Jo, pretending to be a chicken as she comes inside.

On the other side, we put in slats to support a double chicken-wire floor. It's important for chickens to have a lot of circulation, so we didn't want to totally enclose the top of the coop. This will all have straw spread over it anyway, which will help insulate it in winter but still allow air to pass through. This is the side where the nesting boxes will go too.

On the other side, we put in slats to support a double chicken-wire floor. It's important for chickens to have a lot of circulation, so we didn't want to totally enclose the top of the coop. This will all have straw spread over it anyway, which will help insulate it in winter but still allow air to pass through. This is the side where the nesting boxes will go too.

One of the nice features of this coop we're building is that it's portable. Chickens will scratch and pick at ground until it's dirt and mud if you let them, so we want to be able to move the coop to different areas of the yard. We also plan to build our garden in raised beds that are the exact dimensions of the chicken coop's base, so our birds can till, clear, and fertilize the soil in each one!

One of the nice features of this coop we're building is that it's portable. Chickens will scratch and pick at ground until it's dirt and mud if you let them, so we want to be able to move the coop to different areas of the yard. We also plan to build our garden in raised beds that are the exact dimensions of the chicken coop's base, so our birds can till, clear, and fertilize the soil in each one!

The gangplank is added. The area on top is the coop where the chickens are closed in each night for their protection. The area below, accessible via the gangplank, is an enclosed, protected patch of ground where they can scratch around during the day.

The gangplank is added. The area on top is the coop where the chickens are closed in each night for their protection. The area below, accessible via the gangplank, is an enclosed, protected patch of ground where they can scratch around during the day.

The effect from the ground makes the coop look like a UFO.

The effect from the ground makes the coop look like a UFO.

To raise the gangplank, we added a pulley! I've held on to this pulley for a long time, waiting for a chance to put it to good use. Words cannot express how happy I am to have a pulley on our coop. I think it elevates it from clever to ridiculously over-engineered.

To raise the gangplank, we added a pulley! I've held on to this pulley for a long time, waiting for a chance to put it to good use. Words cannot express how happy I am to have a pulley on our coop. I think it elevates it from clever to ridiculously over-engineered.

The gangplank cord runs up through the chicken wire to the pulley, then across to a hole in the frame. Jo's giving it a test run here.

The gangplank cord runs up through the chicken wire to the pulley, then across to a hole in the frame. Jo's giving it a test run here.

But I had to get into the act too. Pull, Gilligan! (Note the inferior, non-pulley-equipped coop in the background...)

But I had to get into the act too. Pull, Gilligan! (Note the inferior, non-pulley-equipped coop in the background...)

Pulling the rope all the way out raises the gangplank, securing the door to the coop. Later we add a cleat--one of those metal double-hooks you see on ships--to the side of the coop so the rope can be tied off and secured when the walkway is up.

Pulling the rope all the way out raises the gangplank, securing the door to the coop. Later we add a cleat--one of those metal double-hooks you see on ships--to the side of the coop so the rope can be tied off and secured when the walkway is up.

Next up is covering much of the outside with chicken wire. The bottom sides and this end of the coop are completely covered.

Next up is covering much of the outside with chicken wire. The bottom sides and this end of the coop are completely covered.

This end was a bit taller than our wire, so Wendi did a bit of metal sewing in addition to our work with the staple gun, just to be sure.

This end was a bit taller than our wire, so Wendi did a bit of metal sewing in addition to our work with the staple gun, just to be sure.

The other end needed a bit more work, as we wanted another door on the bottom to let the chickens out into the yard if we were going to be out there with them. We framed the hatch with 1x3s, but we ran out of the store-bought chicken wire. Luckily (if that's the word) the previous tenants left a huge pile of crap in the yard, including some old metal fencing. Call in the salvage team!

The other end needed a bit more work, as we wanted another door on the bottom to let the chickens out into the yard if we were going to be out there with them. We framed the hatch with 1x3s, but we ran out of the store-bought chicken wire. Luckily (if that's the word) the previous tenants left a huge pile of crap in the yard, including some old metal fencing. Call in the salvage team!

And there we go. A hinged door to let our chickens roam free when we're with them. (We've just put the coop on blocks to be able to work on the lower parts of it better. It actually sits on the ground.)

And there we go. A hinged door to let our chickens roam free when we're with them. (We've just put the coop on blocks to be able to work on the lower parts of it better. It actually sits on the ground.)

Above the lower hatch is another access panel--this one so we can sneak a hand into the nesting boxes and steal eggs.

Above the lower hatch is another access panel--this one so we can sneak a hand into the nesting boxes and steal eggs.

Like the rest of the doors, this has latches we hope will keep out some of the more clever predators our birds are likely to attract.

Like the rest of the doors, this has latches we hope will keep out some of the more clever predators our birds are likely to attract.

Once the ends were finished, it was time to begin adding the metal roofing pieces. Once again, we were pleased to be able to salvage this material rather than have to buy anything new. These are scraps from the metal roofing on our own house. (Or the "human coop," as we've taken to calling it lately.) There's only a half row here because we're going to put on another hinged door--one that will go all the way across the bottom to allow us to add straw and to occasionally rake the coop clean.

Once the ends were finished, it was time to begin adding the metal roofing pieces. Once again, we were pleased to be able to salvage this material rather than have to buy anything new. These are scraps from the metal roofing on our own house. (Or the "human coop," as we've taken to calling it lately.) There's only a half row here because we're going to put on another hinged door--one that will go all the way across the bottom to allow us to add straw and to occasionally rake the coop clean.

Cutting this metal for the roof pieces was easily the worst part of this entire build. We bought a metal-cutting blade for our circular saw, but the thing threw hot burning sparks all over us as we cut it. I still have red marks up my right arm and on my chest. Wendi had hot sparks burn holes in her shirt! And the metal-cutting blade disintegrates as you use it too, so that by our third panel it was so small it was no longer usable. Reluctant to burn ourselves further, I put a metal blade on the jigsaw and gave that a try. It was slower, and shook me so badly I was vibrating like a cartoon character with a jackhammer, but at least it didn't throw hot molten death at us. We could have gotten away with fewer cuts if we had bought new panels and not tried to salvage what we had, but we were bound and determined to recycle as much of our building waste as we could, and we're pretty proud of the result.

Because the bottom half won't join the top half, we wanted to make sure rain didn't run right behind the bottom hinged door, so we created a bit of an awning up top with a 1x3 turned on its side.

Because the bottom half won't join the top half, we wanted to make sure rain didn't run right behind the bottom hinged door, so we created a bit of an awning up top with a 1x3 turned on its side.

After adding the hinged door at the bottom and the flat panels along the back side, we were finished! And it only took us a week. Working four and five hours a day on it. Seriously. This took us FAR longer than we ever expected, keeping us busy until nightfall more than a few times.

After adding the hinged door at the bottom and the flat panels along the back side, we were finished! And it only took us a week. Working four and five hours a day on it. Seriously. This took us FAR longer than we ever expected, keeping us busy until nightfall more than a few times.

We tried to come up with a name that would match the coop's luxuriousness, and we eventually settled on "The Chicken Chateau"--but you have to say the "ch" in chicken like the "sh" sound in chateau. Also considered: "Chicken Chalet" and "La Maison de Poule"--"The House of the Chicken."

We tried to come up with a name that would match the coop's luxuriousness, and we eventually settled on "The Chicken Chateau"--but you have to say the "ch" in chicken like the "sh" sound in chateau. Also considered: "Chicken Chalet" and "La Maison de Poule"--"The House of the Chicken."

Check out the chickens down below, enjoying their courtyard!

Check out the chickens down below, enjoying their courtyard!

Lots of places for Jo to feed them greenery too. Welcome, chickens!

Lots of places for Jo to feed them greenery too. Welcome, chickens!

Jo is on vacation this week in Charleston with her grandparents. While the other employees here at Gratz Industries don't get the week off work, her absence does mean we all get a break...

Jo is on vacation this week in Charleston with her grandparents. While the other employees here at Gratz Industries don't get the week off work, her absence does mean we all get a break...

We've been quiet here at Gratz Industries after a virtual flurry of post-holiday posts--sometimes even two or three a day!--for a few reasons.

First, we could not feel our fingers. The mobile home we're living in until the new house is habitable ran out of fuel oil--again. And just like the last two times--one on a weekend, the other on a holiday--this depletion proved to be horrible timing. We returned home Sunday night from spending a delightful day in the company of friends in Asheville to find the last of our oil gone and the mobile home already down to a chilly 50 degrees. Then the snow began. Lots of snow. And the temperature dropped, both inside and out. It was Wednesday before we could get down the mountain to buy more fuel oil. We had the fireplace in the mobile home, but overnight on the last day, after the fire died, the temperature dropped to 36 degrees. Inside.

But by day, we were toasty and warm. Why? Because our new house was entirely habitable BUT for two piddly, insignificant things: we hadn't drilled a hole for the drier exhaust (even though we haven't moved a drier in yet), AND because one of the switches in the breaker box needed to be an arc fault switch and not a regular breaker switch. (A code thing. It works just fine the way it is now.) That's it. Otherwise, it has working toilets, working faucets, and, most importantly, working heat.

Though our building inspector--regretfully, he admitted--could not give us our certificate of occupancy, he did give us permission to begin moving our things in, which we did with gusto. (Pictures follow.) We also spent every moment we could in the new house, save the shivering evenings before the fire where we ate from our still-functioning mobile home kitchen and slept under piles of blankets. Had we been snowbound one more night, we would no doubt have moved our futon over and slept in the new house, certificate of occupancy be damned. But we managed to remain legal--perhaps more out of perversity than anything--and so we will be able to celebrate even more heartily when the building inspector gives us the final-final go-ahead.

Now the drier hole has been drilled and the vent attached, and the electrician has promised to be out today, around noon, to fix the one problem that remains in the breaker box. After I finish this post, I am calling the building inspector to see if he can come out this afternoon, and perhaps--PERHAPS--we may officially be in tonight. I remain cautiously optimistic. (As I often tell Wendi, with my best Austin Powers voice, "'Caution' is my middle name, baby.")

And so, to the promised pictures!

The newly installed drier vent, from the outside.

And the less distinguished inside.

Jo's playroom/art room, in progress. The quilt is where we eat our picnic lunches.

Jo's new IKEA loft bed!

Jo's reading nook, in progress.

Jo's "closet."

Wendi's craft room hutch.

Wendi's craft room shelves.

The new IKEA wardrobes in the bedroom.

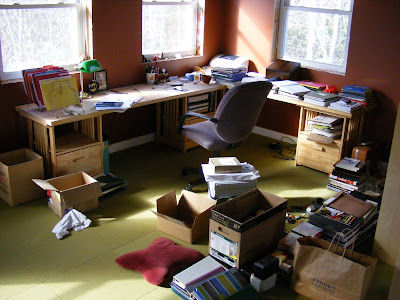

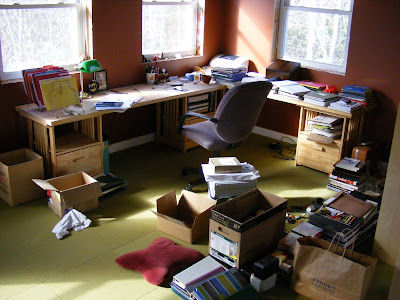

My office, deconstructed.

More bookshelves like that lonely fellow will eventually line the back of those wardrobes, with a corkboard equivalent above them.

More news soon!

We're almost there! We have a list of things left to do on the house, and it's less than one legal pad page long. And three or four of the things on the list must be done by professional plumbers--who have been called!

We're almost there! We have a list of things left to do on the house, and it's less than one legal pad page long. And three or four of the things on the list must be done by professional plumbers--who have been called!

This past Sunday and all day today we've worked at the list--mostly odds and ends. Last minute things that didn't get done along the way. And we're almost through! I ran through the house before dusk today taking pics of the things we've marked off the list. Remember too that for each picture of an outlet or switch-plate cover there were dozens more just like it throughout the house!

Exterior lights - attached!

Exterior outlets - covered!

First floor porch fan - hung!

Hardware chic kitchen counter - constructed!

Kitchen sink - sunk!

Switch plate covers - screwed!

First floor bathroom vanity - assembled!

First floor bathroom vanity light - installed!

Fire alarms - activated!

Jo's bathroom vanity - aligned!

Jo's bathroom vanity light - fabricated!

Jo's cloud light from her room in Atlanta - salvaged!

Second floor - swept!

Third floor fans - suspended!

Master bathroom vanity light - erected!

Master bathroom toilet room floor tiles - arranged!

Master bathroom IKEA wall sconce - hacked!

Third floor porch fan - dangled!

Third floor porch railing -

finished.

We finally had to do it. It's been more than twelve years since either of us bought a car, but it was time to add a new vehicle to the Gratz Industries corporate fleet. And here it is:

We finally had to do it. It's been more than twelve years since either of us bought a car, but it was time to add a new vehicle to the Gratz Industries corporate fleet. And here it is:

A 2008 Subaru Forester. We bought it used, for what we think (based on comparison shopping) was a pretty good deal. And it only has 13K miles on it, so it's still well under warranty. It is also shiny.

A 2008 Subaru Forester. We bought it used, for what we think (based on comparison shopping) was a pretty good deal. And it only has 13K miles on it, so it's still well under warranty. It is also shiny.

As all great cars do, this one needs a name. For years now, we've had "The Jeep" and "The white car." We still have "The white car," but while it's a good, reliable car, it doesn't really deserve a better name. This one, as noted, is shiny. And new. It also inspires the very odd sensation of feeling small on the outside and bigger on the inside. Thus, our first inclination was to call it "The Tardis," which fans of Doctor Who will instantly understand. The problem? It doesn't look very Tardis-y, particularly as the Tardis is blue, and our shiny new car is gold. (Perhaps not the color we would have chosen, but for us the good price trumped the paint job.)

As all great cars do, this one needs a name. For years now, we've had "The Jeep" and "The white car." We still have "The white car," but while it's a good, reliable car, it doesn't really deserve a better name. This one, as noted, is shiny. And new. It also inspires the very odd sensation of feeling small on the outside and bigger on the inside. Thus, our first inclination was to call it "The Tardis," which fans of Doctor Who will instantly understand. The problem? It doesn't look very Tardis-y, particularly as the Tardis is blue, and our shiny new car is gold. (Perhaps not the color we would have chosen, but for us the good price trumped the paint job.)

Instead, Wendi had the idea to call it "Firefly," after the ship in Joss Whedon's sci-fi/western of the same name:

Instead, Wendi had the idea to call it "Firefly," after the ship in Joss Whedon's sci-fi/western of the same name:

Wendi also points out that the Forester has all kinds of hidden compartments for smuggling things in, which fits perfectly with a Firefly.

Wendi also points out that the Forester has all kinds of hidden compartments for smuggling things in, which fits perfectly with a Firefly.

More properly, we suppose, it should be called "Serenity," which is the name of the ship in the show; "Firefly" is just the class of ship. But we like the sound of Firefly better. Besides, we can say, "Let's take the Firefly," and it still works.

And it is shiny.

Meet our new scissor lift! Well, it's ours until next Friday. This little guy is going to help us finish the exterior siding AND get a head start on the insulation that goes in the tall, two-story walls and two-story tall ceiling on the first floor. Once Wendi and Jo get back from school, that is. Today is one of our parent-helper days at Spruce Pine Montessori, so of course we have to wait . . .

Meet our new scissor lift! Well, it's ours until next Friday. This little guy is going to help us finish the exterior siding AND get a head start on the insulation that goes in the tall, two-story walls and two-story tall ceiling on the first floor. Once Wendi and Jo get back from school, that is. Today is one of our parent-helper days at Spruce Pine Montessori, so of course we have to wait . . .

More pics of scissor-lifting to come!

Time for some siding derring-do!

Time for some siding derring-do!

With some loaner scaffolding set up, we were ready to start putting up the next two levels of Hardipanel siding. We got a start last Thursday, working our way along the back of the house over toward the third floor porch. The scaffolding we have only gets us to the bottom of the third story, but hey--if we can't work up, we can work down!

With some loaner scaffolding set up, we were ready to start putting up the next two levels of Hardipanel siding. We got a start last Thursday, working our way along the back of the house over toward the third floor porch. The scaffolding we have only gets us to the bottom of the third story, but hey--if we can't work up, we can work down!

Yes, that's Alan hammering siding on between his legs. You won't see that on HGTV.

Yes, that's Alan hammering siding on between his legs. You won't see that on HGTV.

Nor, probably, will you see this:

Nor, probably, will you see this:

That shot's not so dizzying as it felt, but this next shot gives you a better idea how high up it was--

That shot's not so dizzying as it felt, but this next shot gives you a better idea how high up it was--

Yikes!

But Alan survived.

A little more dangerous was using a kitchen step-stool on top of the scaffolding. We had to do this to be able to reach the top of the fourth row of siding.

Just don't tell our parents we were doing this!

Ah yes, and the always safe hammering across your body while standing on a kitchen step-ladder on top of borrowed scaffolding floored with garden timber. Wendi took these pictures so she could explain what happened to the coroner.

Thankfully, the evidence won't be used in any coroner's inquest in the near future. Instead, when everything was said and done, the results were pretty fantastic.

Siding!

Siding!

More siding!

We made it to the end of the fourth row on the south side of the house, but we didn't have it in us to haul that scaffolding around the corner to the front today. It proved to be a wise decision--the rains that chased us from our work on Saturday began just as we were putting our tools away.

Our favorite tool? Easily the mallet, which allows us to, ahem, beat misaligned siding into place. Not that we have to do that often. Really.

That's the end of the house work for the next few days as Wendi hits the road again, but we're moving right along, and hope to get back to it by next weekend, weather permitting!

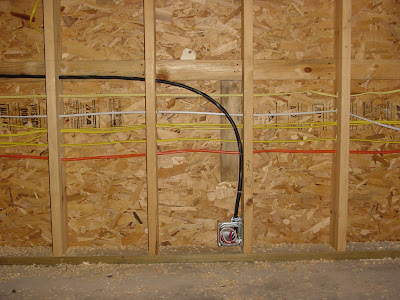

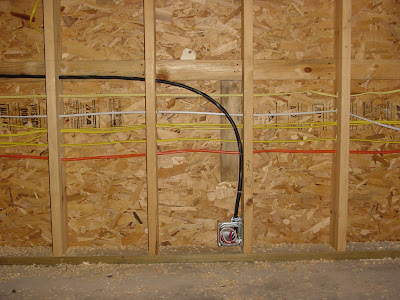

In three quick days, the entire house was wired in by the great guys at KC Electrical. They only roughed in the electrics--we're going to go in and add all the sockets, switches, lights, and fans. That's the level of electric work we've done before on previous homes, so we're pretty comfortable with that. Especially since they were so nice to label everything!

In three quick days, the entire house was wired in by the great guys at KC Electrical. They only roughed in the electrics--we're going to go in and add all the sockets, switches, lights, and fans. That's the level of electric work we've done before on previous homes, so we're pretty comfortable with that. Especially since they were so nice to label everything!

The corner of the kitchen.

A box of wall outlet boxes.

The oven outlet, with lots of other wires running past.

The area that would become our breaker box, a work in progress -

And all spiffy!

And labeled even! This will be a first--actually knowing which breaker to flip when we need to.

Next up--insulation! We've got a guy in town who's giving us a great deal on some old asbestos insulation he's got lying around. Yeah, we know the stuff can kill you, but at these prices we'll take the risk!

(And yes, mom, I'm kidding about the asbestos.)

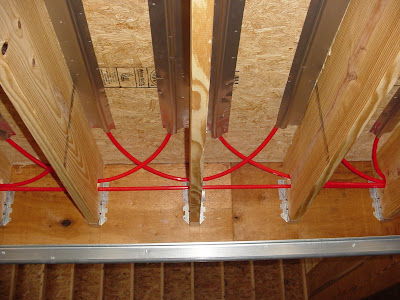

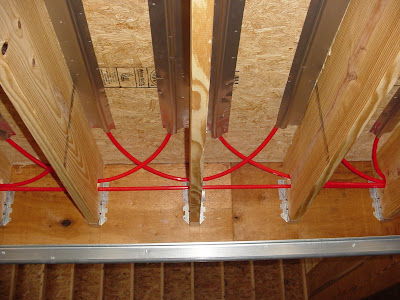

After weeks--nay, months--of slow to no progress on our new headquarters, we finally have some action. Some Heatpex action! Heatpex is is a metal-lined plastic tubing that carries hot water through your floors to provide radiant heat. No air ducts, no blower, no sound, and each "zone" or room can be controlled individually. Mwahahaha.

After weeks--nay, months--of slow to no progress on our new headquarters, we finally have some action. Some Heatpex action! Heatpex is is a metal-lined plastic tubing that carries hot water through your floors to provide radiant heat. No air ducts, no blower, no sound, and each "zone" or room can be controlled individually. Mwahahaha.

The Heatpex yet to be installed is stored on this gizmotron, which allows the guys to pull more through when they need it. Clever.

The Heatpex yet to be installed is stored on this gizmotron, which allows the guys to pull more through when they need it. Clever.

The Heatpex was first run all the way down the length of the floor--in this case, the floor of Wendi's craft room--

The Heatpex was first run all the way down the length of the floor--in this case, the floor of Wendi's craft room--

--and then it was woven back and forth between the joists and covered with this metal covering. The covering holds it to the floor so that the heat radiates right underfoot, and it's metal so it reflects the heat upward. When the installation is finished, we'll then go back and put insulation between the Heatpex and the ceiling below it to further encourage the heat to radiate more up than down.

--and then it was woven back and forth between the joists and covered with this metal covering. The covering holds it to the floor so that the heat radiates right underfoot, and it's metal so it reflects the heat upward. When the installation is finished, we'll then go back and put insulation between the Heatpex and the ceiling below it to further encourage the heat to radiate more up than down.

Ooooh. Pretty.

And lo and behold, the same day the Heatpex installation began, the flooring store finally brought the tile we ordered for Jo's bathroom. It's pretty too.

They ran out before they could finish though, so there are sticky places where little bits of tile should go. This is the one I stepped in without thinking. Watch out, Mr. Rabbit!

With the Heatpex has come warmer weather too, and we here at Gratz Industries are considering taking a week or two of sick leave to put some major effort into the house. And we really are sick--sick of staring at it through the windows of our mobile home. We want to be inside our new home! More images and updates to come . . .

Wendi and I want to get a goat.

Wendi and I want to get a goat.

Seriously.

There's a family down the hill from us that has five of them. The goats hang out on this really steep slope, munching on anything that grows there and keeping it "mowed." We're envious, and we have a steep, unkempt slope of our own what amounts to our "back yard."

Our back yard.

Our back yard. More of our back yard.

More of our back yard.We do not want to mow this. We don't want to mow

anything. We moved away from suburbia to get away from, among other things, a preoccupation with lawn maintenance.

Enter the goat. At least, our plan to get one. We have a few things to get settled first (like, finishing the big house in our front yard we're not living in--more updates on that soon) but we've already broached the topic with my parents. When it comes to things like, "We are moving to the middle of nowhere," "We're painting the outside of our house three different colors," and "We're going to buy a goat," it helps to give my parents plenty of advance warning so they can handle it when we actually do these things.

So my dad, ever helpful person that he is, forwarded me this e-mail ad today:

Never cut the grass again! Buy a goat

Cuts & Fertilizes At the Same Time

Yes, a goat. Not as neat as a lawn mower, but good enough. In one end, out the other. Cuts the grass and feeds the lawn at the same time. Get your own goat today. They do an excellent job of keeping the grass down, although they can be a bit indiscriminate at times.

Yes, a goat. Not as neat as a lawn mower, but good enough. In one end, out the other. Cuts the grass and feeds the lawn at the same time. Get your own goat today. They do an excellent job of keeping the grass down, although they can be a bit indiscriminate at times.

They are not very good at a light trimming of course, big mouthfuls of grass from the center of the lawn is more their thing, not good at neat edges where the grass and the fence line meet, but in general they do a good job. Some customers hang on to their back legs and hold them up to direct their head. Reasons to buy:

- A good investment no gas required

- Highly reliable too (nothing the local vet won’t sort out)

- Affectionate & lovable animals- Environmentally friendly to boot.

- Free goat droppings for the compost pile.

The ad even had a link:

Click Here for Pricing & Shipping InformationSo I clicked. I'll let you click to, so you can see how Dad got my goat. He claims he didn't click through to see that, but given what day it is, I have a hard time believing him.

And trust me, we're still getting a goat.

It's been a while since we had a Gratz Industries HQ update here, I know. I'd like to say that it's because we were very busy--which is partially true--but our frequent Project Runway and Project Barbie posts belie that. The truth is, not much has happened to the house since it was handed over to us. It got door hardware, and a spiffy new trench with little landscaping flags and everything, but the house still stood in its underwear--until now.

It's been a while since we had a Gratz Industries HQ update here, I know. I'd like to say that it's because we were very busy--which is partially true--but our frequent Project Runway and Project Barbie posts belie that. The truth is, not much has happened to the house since it was handed over to us. It got door hardware, and a spiffy new trench with little landscaping flags and everything, but the house still stood in its underwear--until now.

Doesn't look like a thousand dollars worth of siding, does it? But it is. This is cement board siding called HardiBoard. They make it with wood grain and faux board molding, but you know we're too weird to do it straight up like that. We have a very different look in mind, which we'll get to in a minute.

Jo is leaning on enough siding to do about one and a half exterior walls--give or take a few panels. We overbought (we hope) for the first wall both because we're new at this and want to make sure we've calculated right, and because we're going to rip some of that stuff to become the battens, the little strips that cover the siding seams. We figure we can use any overage on the next wall anyway.

Work began by hefting the dang things into place and then hammering them into the sheathing already on the house (hidden behind that "BreatheEZ" housewrap there). Each of these panels is 4 x 8 feet, and weighs about 70 pounds. I kid you not. Lifting them into exactly the right place is a four person job, for which of course we only have two people. Nailing them is a one-person job, which allowed a particular persona non grata to take a shot of my butt. (Which is better than seeing the bald spot on the back of my head, I guess.) Jo likes playing in the rocks we put down to keep the mud from splattering back up on the house, but I was able to enlist her help eventually:

Work began by hefting the dang things into place and then hammering them into the sheathing already on the house (hidden behind that "BreatheEZ" housewrap there). Each of these panels is 4 x 8 feet, and weighs about 70 pounds. I kid you not. Lifting them into exactly the right place is a four person job, for which of course we only have two people. Nailing them is a one-person job, which allowed a particular persona non grata to take a shot of my butt. (Which is better than seeing the bald spot on the back of my head, I guess.) Jo likes playing in the rocks we put down to keep the mud from splattering back up on the house, but I was able to enlist her help eventually:

Jo's pushing the paneling flat for me while I nail it in.

Jo's pushing the paneling flat for me while I nail it in.

Each side of the house is exactly four panels long. Coincidence? Perish the thought. We deliberately designed the house so that we could use 4 x 8 panels without having to cut them. Until we come to the windows, of course. We chose to start with the back wall, here in the shadows, for that reason--only five windows, and not until we get up high. (This is the northern, cold wind side, which is why there are fewer windows. It also faces the woods.) The other reason we started with the back side of the house? Years of weekend warrior experience have taught us a very important lesson: always begin with the least visible place you're working on--that way all your terrible initial mistakes are hidden and by the time you get to the visible stuff you know what you're doing.

Each side of the house is exactly four panels long. Coincidence? Perish the thought. We deliberately designed the house so that we could use 4 x 8 panels without having to cut them. Until we come to the windows, of course. We chose to start with the back wall, here in the shadows, for that reason--only five windows, and not until we get up high. (This is the northern, cold wind side, which is why there are fewer windows. It also faces the woods.) The other reason we started with the back side of the house? Years of weekend warrior experience have taught us a very important lesson: always begin with the least visible place you're working on--that way all your terrible initial mistakes are hidden and by the time you get to the visible stuff you know what you're doing.

Does this tool belt make me look fat?

Two full rows finished! That's as high as we're going on each wall until we rent some scaffolding, so we can spend as little time (and money) on it as possible. Now it's time to paint the stuff!

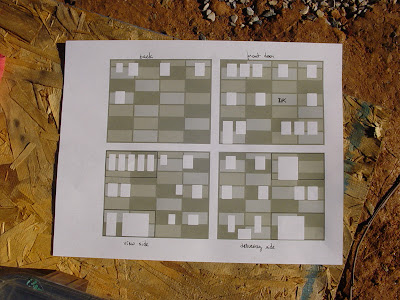

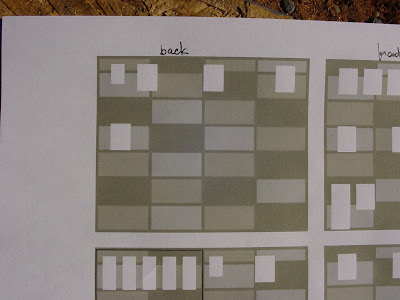

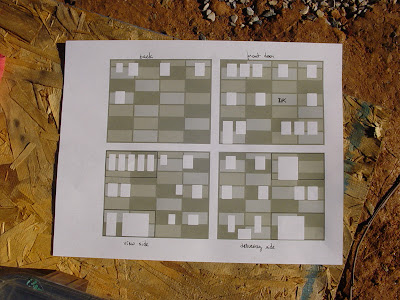

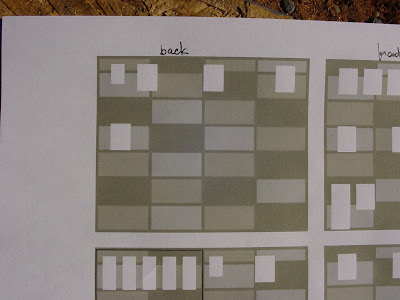

Remember what I said about us never doing things nice and easy? Our grand plan is to paint each of the 4 x 8 panels one of three shades of greenish/gray, to give the house a graphic design kind of look. Here's our game plan, printed out in the four walls of the house:

The top left is the back wall, the one we've started with:

The top left is the back wall, the one we've started with:

Those dark lines in between the panels are the battens we'll have to attach to keep the elements out and hide the seams.

Those dark lines in between the panels are the battens we'll have to attach to keep the elements out and hide the seams.

Wendi begins with the lightest color paint, and I get revenge for that butt shot. Woohoo!

Wendi begins with the lightest color paint, and I get revenge for that butt shot. Woohoo!

And the paint goes on. Wait! It's the same color as the primer! Dang. Still, has to be done, just not as satisfying as the other colors:

And the paint goes on. Wait! It's the same color as the primer! Dang. Still, has to be done, just not as satisfying as the other colors:

Now we're talking! The paints haven't dried yet, so the two lighter ones look very similar. That will change.

Now we're talking! The paints haven't dried yet, so the two lighter ones look very similar. That will change.

And here it is later in the day as the sun sets over the mountain behind us.

And here it is later in the day as the sun sets over the mountain behind us.

We're 1/14th of the way there!

We're 1/14th of the way there!

Oh man, that's a depressing thought.

Check out our newest feature: our own Gratz Industries Company Store, courtesy of Amazon. The link can be found permanently in the sidebar to the right. With this store we can add books we've written and books we're featured in as they're published, as well as books by other authors we're excited about.

Which of us has more books? You'll have to follow the link to find out!

As of Halloween 2007, we are now the proud owners of one half-finished, unusable home. The last half of the money has been paid to the builders, and we're now officially dirt poor again. It looks like there will be no Christmas for one little girl this year--but that's all right, we'll just tell her she's been bad and that Santa doesn't love her anymore.

As of Halloween 2007, we are now the proud owners of one half-finished, unusable home. The last half of the money has been paid to the builders, and we're now officially dirt poor again. It looks like there will be no Christmas for one little girl this year--but that's all right, we'll just tell her she's been bad and that Santa doesn't love her anymore.

So the first thing we did as new homeowners was to put door handles and deadbolts on the doors. Have you shopped for door handles lately? These things can be expensive. We bought three door handles (two for the exterior, bottom-floor doors and one for the door to our third floor porch) and three deadbolts. Total cost: $230! That cost per square foot keeps inching up and up, but we'll end up saving on things like labor and expensive cabinetry in the long run.

We're making a list of all the things left to do on the house (because we like lists), and next up is the exterior siding, which we'd really like to get up by winter to help protect the house. Oh, and there's the big pile of crap in the front yard we want to go through to salvage anything useful . . .

It's been quite some time since we had a Gratz Industries HQ update for you, but truth be told, there hasn't been much new. In fact, we think the builders are almost done with their part of the work, which means it's almost time for us to put on our hardhats and get to work on all the things we left for ourselves to do. Like the plumbing. And the heating. And the electricity. And the exterior siding. And the interior drywall. And the . . . you get the picture. Right now, ambitiously, we're hoping to be living in the new house by April. One of us may have to take up prostitution to afford that, but hey - you do what you have to do.

It's been quite some time since we had a Gratz Industries HQ update for you, but truth be told, there hasn't been much new. In fact, we think the builders are almost done with their part of the work, which means it's almost time for us to put on our hardhats and get to work on all the things we left for ourselves to do. Like the plumbing. And the heating. And the electricity. And the exterior siding. And the interior drywall. And the . . . you get the picture. Right now, ambitiously, we're hoping to be living in the new house by April. One of us may have to take up prostitution to afford that, but hey - you do what you have to do.

Here's our first-floor deck, flanked now by two windowed garage doors. We had a large, all-glass garage door in our Atlanta loft, and we loved it. These partial glass doors are a concession to the colder climate, but should give us an amazing open-air feel two-thirds of the year. (The porch will be screened in too, so no bugs!)

Here's our first-floor deck, flanked now by two windowed garage doors. We had a large, all-glass garage door in our Atlanta loft, and we loved it. These partial glass doors are a concession to the colder climate, but should give us an amazing open-air feel two-thirds of the year. (The porch will be screened in too, so no bugs!)

Here's the view from the inside. You'll be able to see green through there once the mobile home is dragged away. Well, it will be brown dirt we'll see first, but we'll bring the space back to life. This interior space will be our kitchen, dining room/library, and living room, with the garage doors as a rather dynamic backdrop, methinks.

Here's the view from the inside. You'll be able to see green through there once the mobile home is dragged away. Well, it will be brown dirt we'll see first, but we'll bring the space back to life. This interior space will be our kitchen, dining room/library, and living room, with the garage doors as a rather dynamic backdrop, methinks.

Here's the front door. We couldn't put windows in this wall because of the stairs, so we put one in the door!

Here's the front door. We couldn't put windows in this wall because of the stairs, so we put one in the door!

The third floor got doors too. Here you can see the French doors in the bedroom. They're boarded over right now to keep them closed--there's no hardware in any of the doors yet.

The third floor got doors too. Here you can see the French doors in the bedroom. They're boarded over right now to keep them closed--there's no hardware in any of the doors yet.

And that's it for the update. There can't be much left, but the builders haven't been by in a while, and we're no hurry to call them up and ask where they are because if they're done we owe them the second half of the money. 8-/ We have it, we have it - but the longer we wait to give it to them the more brief the time we have to live with levels our bank accounts haven't seen since we were in college. Yikes! So, um, maybe I can sell another book this month . . . I know I have some old stuff laying around here somewhere . . .

Not much new to report on the new headquarters. Last week the place was spiffed up, and these short walls were added to the second and third floors. The builders had left them until last to facilitate moving large boards up and down through the open spaces without having to scale (or spear) the walls.

Not much new to report on the new headquarters. Last week the place was spiffed up, and these short walls were added to the second and third floors. The builders had left them until last to facilitate moving large boards up and down through the open spaces without having to scale (or spear) the walls.

They also added a rubber seal on the third floor patio--which also happens to be the second floor roof. At least a quarter of the roof, that is. I'm sure we would have thought of that ourselves. After the first major rain.

They also added a rubber seal on the third floor patio--which also happens to be the second floor roof. At least a quarter of the roof, that is. I'm sure we would have thought of that ourselves. After the first major rain.

Can I say again how glad I am that Marvin and his crew are doing this phase of the work? Now, if we just had more money, we could pay them to do the REST of it. As it is, we're going to have to wait for the money to come in in chunks. (Think of them as . . . book-sized chunks, if you will.) In a way this will work fine though, as we wouldn't have time to finish the rest of the house right away even if we had the money. Then again, if we had the money, we could just pay someone to finish it . . . wait, I think this line of reasoning is becoming circular.

Can I say again how glad I am that Marvin and his crew are doing this phase of the work? Now, if we just had more money, we could pay them to do the REST of it. As it is, we're going to have to wait for the money to come in in chunks. (Think of them as . . . book-sized chunks, if you will.) In a way this will work fine though, as we wouldn't have time to finish the rest of the house right away even if we had the money. Then again, if we had the money, we could just pay someone to finish it . . . wait, I think this line of reasoning is becoming circular.

Tonight: an object lesson in the difficulties of getting good publicity for your novel.

It was a banner week for Gratz Industries, as two of our employees made the local weekly paper, the Mitchell News-Journal. ("Serving Bakersville, Little Switzerland, Spruce Pine, and the rest of beautiful Mitchell County")

First, on page 3A, was this feature story. (Click the image to see it larger.)

As Wendi says, you gotta love a town where a new crosswalk is worthy of a page three feature story. According to the caption, Jo is one of the fairly indistinguishable little kids in raincoats crossing the street at the new crosswalk. Not only is her picture in the paper, she was interviewed!

As Wendi says, you gotta love a town where a new crosswalk is worthy of a page three feature story. According to the caption, Jo is one of the fairly indistinguishable little kids in raincoats crossing the street at the new crosswalk. Not only is her picture in the paper, she was interviewed!

When asked if she liked it, Jo Gratz, a student at the school, responded by saying, "yeah, mmmhmm."

That's good press! But Gratz Industries wasn't done. This little item was featured on page 3B. (Again, click to read larger.)

Jo gets page 3A, Dad gets page 3B--the "Arts" page. Which, by the way, is in the Sports section. No picture, as you'll note, and no quotes. I did not warrant an interview. Perhaps if I had announced my new book while using the new crosswalk in town? And of course to add insult to injury, the headline misspells my last name, when they went to all the trouble of spelling it correctly throughout the copy.

Getting coverage from your local media is always a hairy proposition. I usually advise authors to focus their publicity efforts demographically, not geographically, but that's still no reason to ignore your hometown media. Admittedly, Mitchell County has only been my home since April of this year--but I had hoped for a bit more coverage!

Then again, considering I never got coverage from either the

Knoxville News Sentinel or the

Atlanta Journal-Constitution, perhaps I should be thankful they mentioned me at all . . .

View Next 25 Posts